Difference between closed ink cup system and open ink tray system

from Catherine

Difference between closed ink cup system and open ink tray system

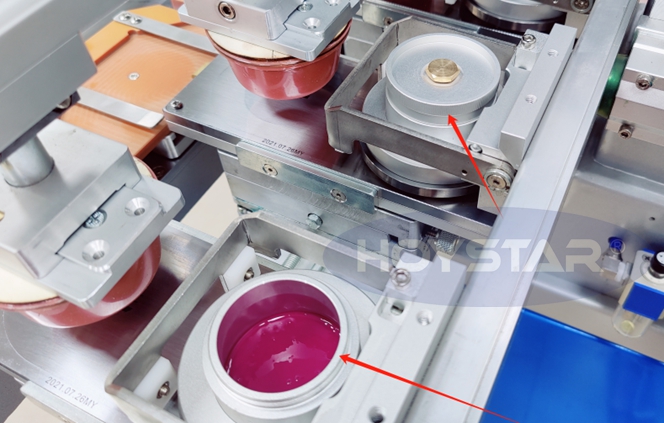

The closed ink cup system and open ink tray system are two different types of ink delivery systems used in pad printing, a printing process that involves transferring a 2D image onto a 3D object. These systems are specifically designed for the unique requirements of pad printing machines. Here are the key differences between the two:

1. Ink Containment:

- Closed Ink Cup System: In this system, the ink is contained within a sealed cup. The cup has a ceramic or steel ring with a precise doctoring blade that wipes excess ink from the printing plate, leaving only the image in the etched or engraved areas. This design minimizes ink evaporation and contamination.

- Open Ink Tray System: In contrast, the open ink tray system uses an open container (tray) to hold the ink. The printing plate is partially submerged in the ink, and excess ink is typically scraped off by a doctor blade or similar mechanism.

2. Ink Consumption:

- Closed Ink Cup System: Generally, the closed ink cup system consumes less ink because the ink is contained and protected from external elements that could cause evaporation or contamination.

- Open Ink Tray System: This system may consume more ink as the open nature of the tray exposes the ink to the air, leading to faster evaporation.

3. Ink Changeover:

- Closed Ink Cup System: Changing ink colors in a closed ink cup system is often quicker and more straightforward. The sealed cup minimizes the risk of cross-contamination between different ink colors.

- Open Ink Tray System: Changing ink colors in an open ink tray system may take longer, and there is a higher risk of color contamination because the ink is exposed.

4. Cleanliness and Maintenance:

- Closed Ink Cup System: This system is generally cleaner and requires less maintenance due to the enclosed nature of the ink. It is also less prone to dust and debris contaminating the ink.

- Open Ink Tray System: Because the ink is exposed in an open tray, there is a higher risk of external contaminants entering the ink, requiring more frequent cleaning and maintenance.

5. Ease of Operation:

- Closed Ink Cup System: Often considered more user-friendly and easier to operate, especially for those new to pad printing, as it provides a more controlled and contained environment for the ink.

- Open Ink Tray System: May require more attention to detail during operation, and operators need to be mindful of factors like evaporation and contamination.

The choice between a closed ink cup system and an open ink tray system depends on factors such as the specific printing requirements, the type of objects being printed, and the level of precision and cleanliness needed for the printing process.

Contact Us

Address : Guangdong province China

Postal code : 523860

Tel : +86-769-85377425

Fax : +86-769-82926182

Facebook: [email protected]

E-Mail: [email protected]

Copyright © Dongguan Hoystar Printing Machinery Co., Ltd. All Right Reserved. 51LA

Add:No.2,Zhenglong 2nd Road,Hengzeng Street,ChanganTown,Dongguan city,Guangdong province China

Tel : +86-769-85377425 Fax : +86-769-82926182

Screen printing machine | Pad printing machine | Infrared Drying Machine | UV Curing Machine | Hot Stamping Machine | Heattransfer Machine | Uv-exposure-machine

Rotate screen printing machine | Flat bed screen printer| Cylindrical screen printer | Flame treatment equipment |Screen pringer | Automatic screen printing machine

Socks screen printer | Mini pad printing machine | Ruler screen printing machine | Mini screen printer supplier | Screen printing conveyor dryers | T-Shirt Printing Equipment

![]() Facebook

Facebook ![]() Youtube

Youtube ![]() Twitter

Twitter ![]() Google

Google ![]() Arabic

Arabic ![]() Spanish

Spanish ![]() Portuguese

Portuguese ![]() Russian

Russian ![]() French

French ![]() Turkish

Turkish ![]() German

German ![]() Italian

Italian

Email Us

Email Us Catherine

Catherine